Continuing with platters, I've trimmed up the ones from last week with mixed results. Coming up with a dozen or two finished ones will be the challenge I expected. Of the four I threw last week, two survived. While trimming, I carved through the bottom of a few of them. I’m getting a better feel for judging their thickness and exactly how dry they need to be before starting to trim. I also made myself a tool to support the platters and ease back strain while carving the foot.

I had 8” and 12” high-density foam circles cut and then glued them to bats.

I cut high-density foam circles and then glued them to old bats. Bats are a thin slab of wood, plaster, or plastic used to support pottery forms while throwing. Because the bat can be lifted from the wheelhead, there's no need to directly handle your clay project and risk distorting its shape. The foam lifted the trimming surface four inches, allowing me to keep my back straight. The foam also supports the platter floor, keeping it flat while preserving the rim from warping now that it's not bearing the platter's weight. I use rubber balls in varying sizes to support the centers when trimming bowls.

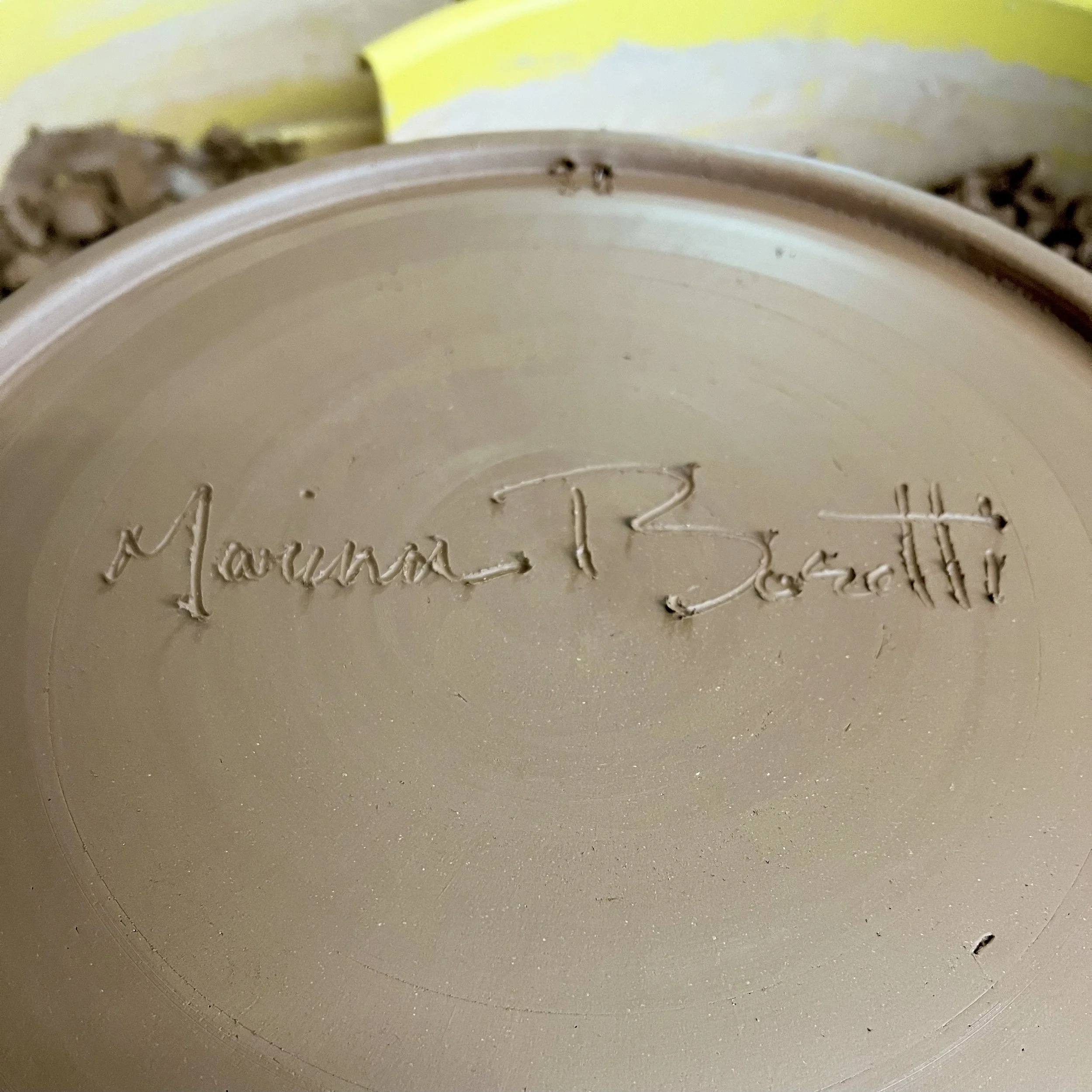

Here’s the bottom of the platter trimmed, signed, and holes have been added for easy hanging. When the platter is dry I’ll knock those bits off with a scrubby pad making to make the signature smooth.